Neodymium Magnet Prices Explained: It‘s Not Just About Strength

Time:2025-12-23

Views:633

If you‘ve ever considered buying neodymium (NdFeB) iron boron magnets, you‘ll understand that the price tags can be quite perplexing. Two magnets that look exactly the same in shape may come with vastly different price tags. Let‘s delve into what truly influences these figures, avoiding the use of technical jargon.

First, let‘s talk about the elephant in the room: raw materials. The price of your magnet is deeply tied to the cost of (rare earths) like neodymium (Nd) and praseodymium (Pr). In 2025, the price of key materials like praseodymium-neodymium oxide has seen significant fluctuations, directly impacting magnet costs. When these commodity prices jump due to supply factors, the price of the finished magnet follows.

Now, about those confusing grade codes like N42 or N52SH. Think of the number as the "power rating" or maximum energy product. A higher number means a stronger magnet. The letters that follow (M, H, SH, UH, EH) are arguably more important—they indicate the magnet‘s coercivity, or its resistance to losing strength when exposed to heat or opposing magnetic fields. An N52 magnet is strong, but an N52UH magnet is strong and can work in much hotter environments. That enhanced performance for demanding applications (like inside a hot car motor) comes at a higher price.

Since neodymium magnets rust easily, a protective coating is non-negotiable. Your choice here is a balance of cost, environment, and lifespan. A standard nickel-copper-nickel plating is a common, cost-effective solution for many uses. However, for harsh conditions (e.g., constant moisture, salt spray), more advanced and expensive options like specialized physical vapor deposition (PVD) coatings might be necessary for long-term reliability. The coating adds a layer of cost, but skipping it is far more expensive if your magnet fails.

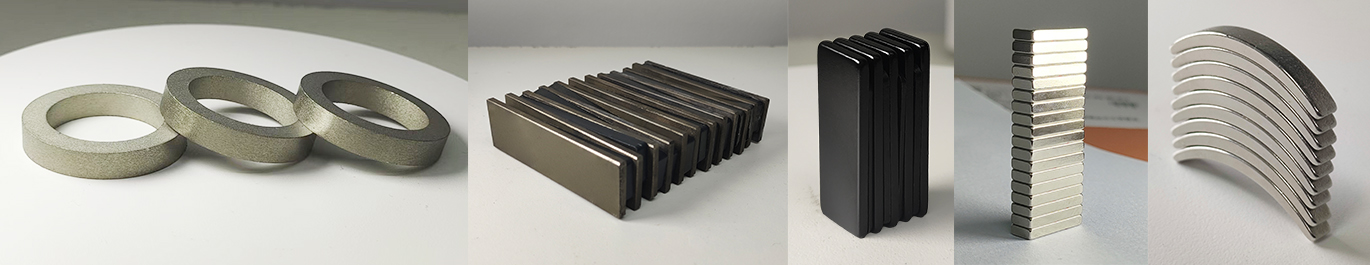

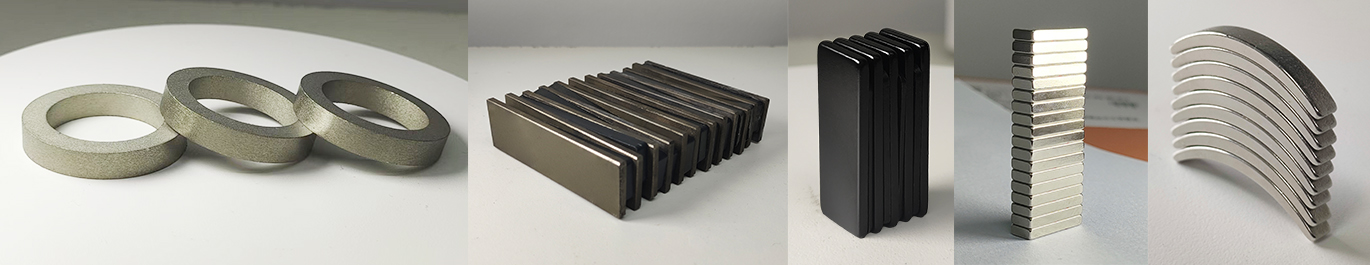

Finally, customization shapes the final price. While standard blocks and discs are readily available, anything non-standard incurs extra costs. This includes precise sizing, complex shapes (like arcs or rings), tight tolerance grinding, and specific magnetization patterns. Each additional machining step adds labor and reduces material yield, increasing the unit price.

In short, the magnet‘s price tag is a story of its composition, its capabilities, its durability, and its shape. Understanding these elements helps you move from wondering "why is it so expensive?" to confidently knowing "this is the right magnet for my project and budget."

How to choose a reliable magnet supplier? Tecomag tailors magnet solutions for you! Please send your specific requirements to sales01@tecomag.net and we will respond immediately!