Don‘t Overpay! How to Choose the Right Ferrite Magnet Grade (Y30 vs Y35 vs Y40)

Time:2025-12-12

Views:685

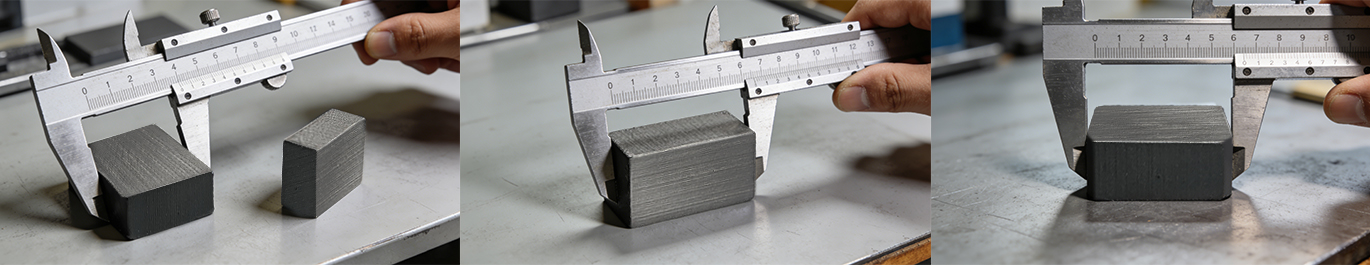

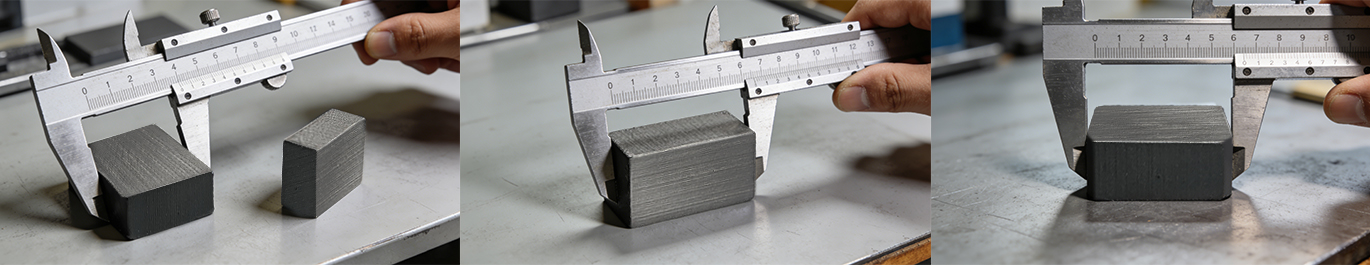

First up, the common specs you’ll encounter. When we say “ferrite blocks,” think of those dark gray, ceramic-like rectangles or squares. The basic specs are, of course, length, width, and thickness. But here’s a pro tip: pay close attention to the tolerance. A tighter tolerance means more precision, which might be necessary for automated assembly, but it also nudges the price up. If your design has a bit of wiggle room, standard tolerances can save you good money. Then there’s the surface. Most ferrite blocks come uncoated—they’re generally corrosion-resistant enough for indoor use. But if your application faces humidity or mild chemicals, a simple epoxy coating might be a wise, low-cost insurance.

Now, let’s chat about grades. This is where the magnetic performance is defined. You’ll often see codes like Y30, Y35, and Y40. That number essentially tells you the magnetic strength or energy product. Y30 is the workhorse—reliable, widely available, and the most cost-effective. It’s perfect for many standard applications. Y35 gives you a stronger pull, a step up for designs needing a bit more power without a crazy price jump. Y40 is the high performer, but here’s the thing: the cost increase from Y35 to Y40 is often more significant than from Y30 to Y35. So, ask yourself: Do I need that top-tier performance, or is Y35 the sweet spot? Over-specifying is a common way to blow the budget.

Which brings us to the big picture: value for money. The cheapest piece price isn’t always the best deal. Think Total Cost of Ownership. A slightly higher-grade magnet (like Y35 over Y30) might allow you to use a smaller or thinner block in your design, saving on material and space overall. Always consider supplier reliability. Can they deliver consistent quality batch after batch? A small price difference means nothing if magnets vary in size or strength, causing production line stoppages. For large orders, ask about tooling charges for custom shapes and their Minimum Order Quantities (MOQs). Building a good relationship with a communicative supplier is priceless—they can help you navigate these exact choices.

In the end, it’s about matching the magnet to your actual need. Don’t buy a Ferrari engine for a city commuter. Define your required magnetic force, understand your environment, choose the most economical grade that safely meets the spec, and partner with someone you trust. Get a few samples, test them in your actual application—it’s the best way to be sure.

Pursuing quality and efficiency? Tecomag‘s ferrites and components are your ideal choice! One-stop service. Welcome to contact us at any time: sales01@tecomag.net