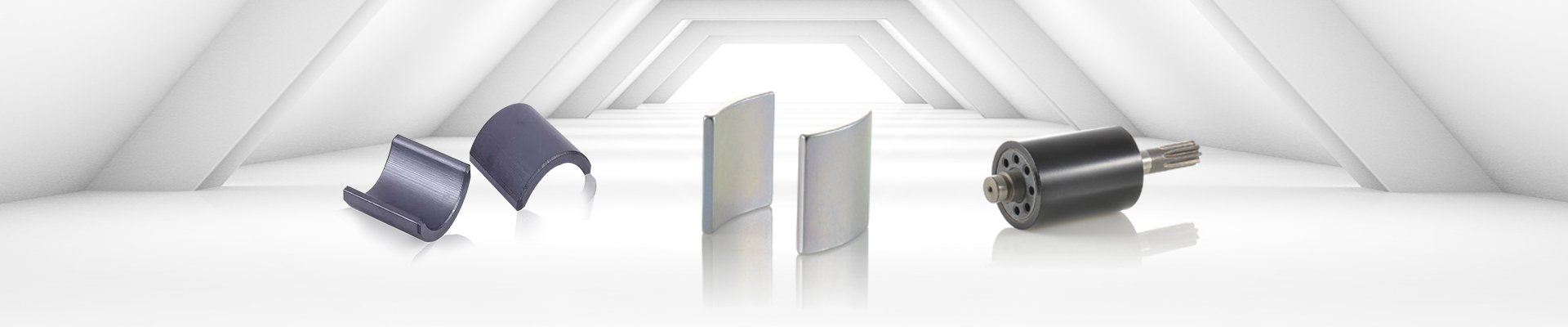

Products

Contact Us

|

Claire Wu |

|

+86-17724716673 |

|

+86-755-21017515 |

|

sales06@tecomag.net; info@tecomag.net |

|

A Building, ICC Park, No. 163, Huawang Road,Dalang Street, Longhua District, Shenzhen, Guangdong, China, 518109 |