Surface Mount vs Interior Magnets: Understanding BLDC/PMSM Motor Design Choices

When designing brushless DC or permanent magnet synchronous motors, one of the most fundamental decisions engineers face is choosing between surface-mounted magnet (SPM) and interior permanent magnet (IPM) configurations. Each design offers distinct advantages that make them suitable for different applications and performance requirements.

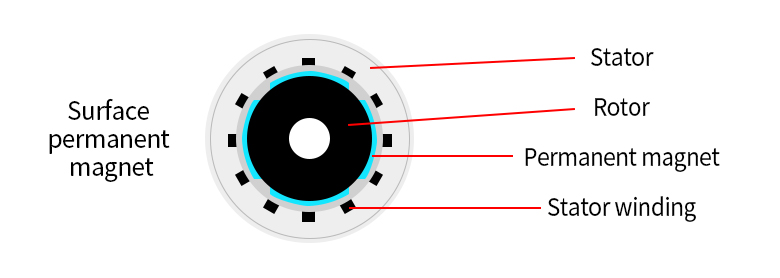

Surface-mounted magnet designs feature magnets placed on the outer surface of the rotor, typically secured by adhesives or retaining sleeves. This configuration offers several significant benefits, including simpler manufacturing processes and lower production costs. The magnetic field distribution in SPM designs is more sinusoidal, resulting in smoother operation and reduced cogging torque. These characteristics make SPM motors particularly well-suited for applications where noise minimization is crucial, such as HVAC systems, medical equipment, and precision instruments.

The relative simplicity of SPM designs also contributes to their reliability. With fewer mechanical components and straightforward construction, these motors often demonstrate excellent long-term performance in continuous operation scenarios. However, the exposed magnet placement does present challenges in high-speed applications, where centrifugal forces may require additional mechanical retention solutions.

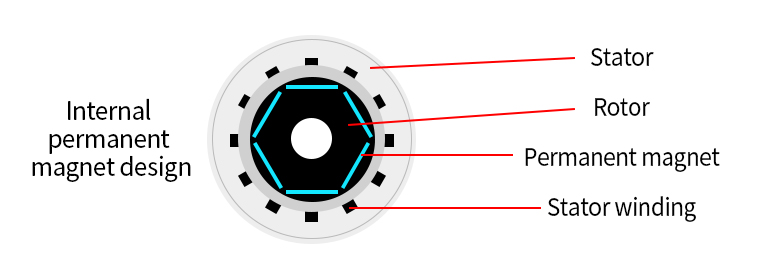

Interior permanent magnet designs incorporate magnets embedded within the rotor structure itself, usually in slots or cavities. This arrangement creates multiple important advantages that have made IPM designs increasingly popular in demanding applications. The embedded magnet placement provides inherent mechanical security, allowing for much higher operating speeds without concern for magnet detachment. The rotor iron between magnets also contributes to structural integrity while helping to shape the magnetic field.

Perhaps the most significant advantage of IPM designs lies in their magnetic performance characteristics. These motors naturally exhibit reluctance torque in addition to magnetic torque, resulting in higher overall torque density and improved efficiency across a wider speed range. This combination makes IPM motors particularly valuable in applications requiring high power density and variable speed operation, such as electric vehicles, industrial drives, and aerospace systems.

The choice between SPM and IPM designs ultimately depends on specific application requirements. SPM designs typically offer better performance at lower costs for fixed-speed or narrow speed-range applications where simplicity and smooth operation are priorities. Their predictable magnetic characteristics and ease of manufacturing make them excellent choices for volume production in consumer and commercial applications.

IPM designs, while generally more complex to manufacture, provide superior performance in applications demanding wide speed ranges, high power density, and robust operation under challenging conditions. The ability to leverage reluctance torque allows IPM motors to maintain high efficiency across various operating points, making them ideal for traction applications and other variable speed scenarios.

Recent advancements in both technologies continue to blur the traditional boundaries between these designs. Improved manufacturing techniques have reduced the cost differential, while new magnetic materials and thermal management approaches have enhanced performance characteristics. Modern simulation tools also enable more optimized designs that maximize the benefits of each configuration.

Understanding these fundamental design differences is crucial for selecting the right motor technology for specific applications. Whether prioritizing cost-effectiveness and simplicity with SPM designs or pursuing maximum performance and efficiency with IPM configurations, both approaches continue to evolve and find new applications across industries. As motor technology advances, the distinction between these designs becomes increasingly nuanced, offering engineers more opportunities to tailor motor characteristics to precise application requirements.

Tecomag high quality permanent magnets (Ndfeb/Ferrite) and components, help your product upgrade! Welcome to email: sales01@tecomag.net